This is Part 14 from 125 Building Blocks for Your Bakery Business.

This chapter explores the best ways you can streamline your production kitchen while maintaining consistent, reliable, high-quality products, even when employees are doing the work instead of you.

Streamline Your Production

We have a saying in the food industry: “If you have time to lean, you have time to clean.” In commercial bakeries, it is forbidden to stand in front of the machine watching the batter mix. Likewise, it is forbidden to stand in front of the oven waiting for the cake to be done. Whenever the machines are mixing and baking, we multi-task.

For example, we don’t prep all of our ingredients at once before beginning the mixing process. We prep only what is needed to begin. Then as the first set of ingredients are mixing in the machine, we measure what is needed next. That way, no time is spent standing and watching. All time is used most effectively.

Methods for Streamlining Production

- Measure as you go

- Make large batches instead of small batches of every recipe element

- Freeze excess inventory for use later on

- Bake in the morning, so product has time to cool

- Decorate in the afternoon, while product is cooling

- Execute every task in the largest possible volume

Streamlining Example: Cake Making

Making a decorated cake from start to finish is a tedious job that involves many different stages. Each stage requires a different kind of equipment and setup. Setting up then breaking down each stage of the process is tedious. You don’t ever want to repeat those actions any more times than is necessary. That is why whether you are making two cakes or two hundred cakes, it is more efficient to fully complete each stage on all cakes before moving on to the next.

According to my professional system for filling cakes in the pan, here are the stages:

- Mixing the sponge

- Baking the sponge

- Making the fillings

- Slicing the cake layers

- Assembling the filling layers

- Freezing the filled cakes

- Defrosting and de-panning the cakes

- Frosting the cakes

- Decorating the cakes

Let’s examine the first stage: Mixing the sponge. The sponge is the term for any kind of baked cake element (not including the filling). We’ll investigate how long it takes to execute this task three different ways.

First Test: mixing batter for a single cake

Second Test: mixing the batter for 100 cakes

Third Test: mixing the batter for 100 cakes, 10 cakes at a time

Efficiency Test #1: Mixing the batter for one cake

Item by item, it takes approximately this much time to get a cake into the oven:

4 minutes to collect mixing equipment

1 minute to ready the pan

5 minutes to collect ingredients

5 minutes to measure the ingredients

5 minutes to mix the batter

0 minutes to pour the batter into the pan (this takes a matter of seconds)

10 minutes to wash dishes and clean counters

5 minutes to put ingredients and equipment away

Total amount of time to execute these tasks for 1 cake = 35 minutes

Efficiency Test #2: Mixing the batter for 100 cakes

When you make 100 cakes, assuming you have the right sized production equipment to do so all at once, I estimate that it takes this long:

4 minutes to collect mixing equipment

10 minutes to ready the pans

10 minutes to measure the ingredients

5 minutes to mix the batter

10 minutes to portion the batter into the pans

40 minutes to wash dishes and clean counters

5 minutes to put ingredients and equipment away

Total amount of time to execute these tasks for 100 cakes = 84 minutes

Total amount of time per cake = 50 seconds

Efficiency Test #3: Mixing the batter for 100 cakes, 10 at a time

Now let’s assume you still need to make 100 cakes but with your equipment, you can only manage to produce ten at a time. Some tasks would only need to be done once. Others would have to be repeated ten times. It would take approximately this long:

4 minutes to collect mixing equipment

2 minutes to ready the pans 10 times = 20 minutes

7 minutes to measure the ingredients 10 times = 70 minutes

5 minutes to mix the batter 10 times = 50 minutes

2 minutes to portion the batter into the pans 10 times = 20 minutes

60 minutes to wash dishes and clean counters

5 minutes to put ingredients and equipment away

Total amount of time to execute these tasks for 10 cakes made 10 times = 229 minutes

Total amount of time per cake in this instance = 2 minutes + 20 seconds

Efficiency Comparison

Now let’s compare the time spent on the baking tasks with all three scenarios:

35 minutes = Time spent per cake when making one cake at a time

2 minutes + 20 seconds = Time spent per cake when making ten cakes ten times in a row

50 seconds = Time spent per cake when making 100 cakes at once

Conclusion: Baking 100 cakes at once is 42 times more efficient per cake than baking a single cake. Baking ten cakes ten times in a row is only 8.6 times more efficient than baking a single cake at a time.

Now consider all the stages of making a cake that follow the baking stage such as filling, frosting, and decorating. The same increase in efficiency applies to those tasks when you make one cake versus 100 cakes versus ten cakes, ten times in a row.

As a small bakery, you will be competing against commercial bakeries that have the production capacity to make 100 or more cakes at once. That level of speed brings their labor costs down, which in part is how commercial bakeries can afford to sell their products at lower prices.

Another advantage to working at high volume is that you have the opportunity for more practice. With repetition, your movements become sure and fluid, increasing the number of desserts you can produce per hour. Efficient, high volume production is the goal in this industry.

Maintain Consistency of Product

Every time you make cookies and cakes, do they come out the same? They should. Aside from when you may be improving upon a recipe, your products ought to be consistently the same size, shape, and quality. A customer who enjoys your chocolate chip cookie once will expect to have the same experience a second time around. A customer who paid a certain price for a cake will expect to receive the same sized cake the next time around. Consistency leads to higher customer satisfaction and loyalty. Consistency is also the only sure way to cost and price your products accurately.

Consistency requires methodical systems for measuring. For a batch of 6” cakes, the amount of batter that goes into each pan should be weighed on a scale or measured using a scoop so each one is the same. I prefer to use color coated portioning scoops to deposit batter into pans. It’s a clean way to move batter and it yields consistent results. I make notes on the recipes to remind myself how much batter should go into each pan. For example, two white scoops per 7” pan. Some bakeries measure batter using a scale. They place the empty pan on top of the scale then add the batter to reach a predetermined “pan weight” (i.e. the weight of the pan + the amount of batter needed).

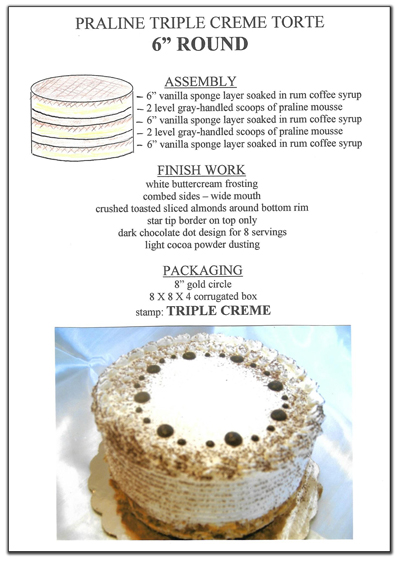

As for the filling and decorating stages, I recommend keeping a master element sheet on file for each product so there is a system for how much filling goes between layers and in what order. Every single detail from the preparation of the baking pan to the decorative elements should be recorded and maintained for consistency. All this information is also needed for costing out products, so a good system like this serves dual purposes. Here is an example of a master decorating sheet that I created for one cake in a product line.

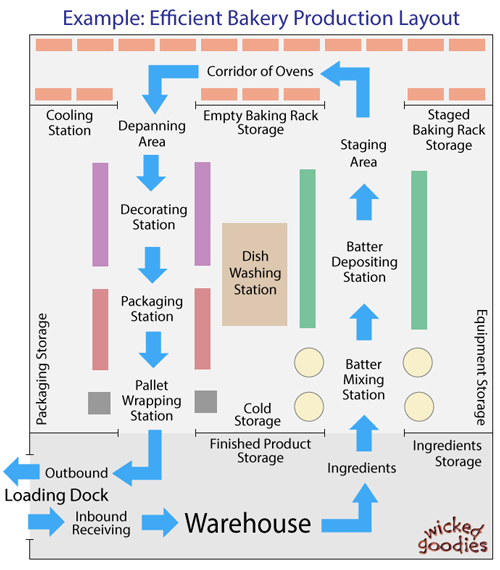

Streamline Your Kitchen Setup

The layout of your kitchen has a significant impact on your production efficiency. In an ideal kitchen, the least amount of steps and reaches of the arm should be necessary between tasks. The layout should be designed to make your job easy and your motions swift. Here are some of the basic tenants of an efficient kitchen setup:

- Prep tables and equipment are arranged in the order that production occurs.

- Tools and ingredients are stored within reach of the areas where they are most often used.

- Tools and ingredients that are rarely used are stored furthest from the production area.

- Tabletops remain clear at all times, except during production.

- Table space is reserved for production, not storage.

Efficiency Example #1: Cheesecake Hose

In one of the wholesale bakeries where I once worked as the pastry chef, a new oven was installed next to the pastry kitchen. The executive chef, who for years had watched my staff sloshing buckets of hot water to and from the ovens in order to make hot water baths (for cheesecakes) installed a special hose, which he hooked up to the hot water line so we could fill the pans with hot water right in front of the oven. It was a genius idea that saved us the trouble of having to fill and slosh buckets around. That one little custom addition increased our efficiency quite a bit over time. It also eliminated a safety hazard. After that, we had no more puddles on the hallway floors.

Efficiency Example #2: The U-Shaped Facility

A baking factory where I once worked had an especially smart setup. The production facility was organized in a U-shape, with both ends of the U facing the warehouse. Ingredients and supplies entered the warehouse, cycled through the production area, then exited the warehouse in the form of finished products. The brilliance of this setup was that as the products advanced from station to station, nothing had to double back or travel any lengthy distance. The entire operation moved in one direction using minimal waste of effort and time.

Prepare for the Eventuality of Employees

In everything that you do as a bakery manager, try to set up systems that will allow you to one day step out of every single role that you started out doing. In the beginning, you will wear many different hats. You will be the baker, the decorator, the salesperson, the marketing director, and the owner all in one. As you do them, think about how you can simplify each one of those jobs by establishing systems.

Writing your own user manuals will make it easy to train employees to take over your positions. If you don’t create systems then it will be very hard to step out of each role. If you continue to play every role, then your hands will be full for as long as you remain in business.

When it comes to hiring employees, you will invariably draw interest from culinary students and people looking for a career change. The bakery industry attracts hobby bakers and middle-aged professionals who are unsatisfied with their career. Many of these types are eager to learn for their own self gain, because they plan to open their own bakery business one day. This is not the ideal candidate, because it means they are likely to stay for a short time and then possibly use your recipes and concepts to open a competing business nearby. The best type of person to look for is one who is eager to contribute.

The path to avoiding or curtailing the risk of the self-serving type of employee is to require all new staff to sign a non-compete agreement upon being hired. In the interview process, be upfront about your plan to do so. This will discourage interest from people who are just looking to use you for your knowledge.

In the food industry, good staff is hard to find. Cooking jobs rarely require much in terms of education and qualifications so they tend to attract less professionally inclined individuals. The rate of turnover is high in this field. Either because they seek to learn or because they get tired of monotonous labor, food industry workers tend to bounce around from job to job. It’s harder to find people who are willing to stay put. Examining an applicant’s job history and confirming their length of time spent at past jobs is a good way to determine if that person is a long term or short term prospect in terms of longevity.

This is the end of Part 14 from 125 Building Blocks for Your Bakery Business.

Return to the Table of Contents or continue to Part 15 – Bakery Marketing Strategies

Related Material